BMI - EMEA

Europe, Middle East and Africa

Current Projects - EMEA

During November 2024, BMI was invited to carry out an initial system audit and a subsequent on-site compliance assessment conducted collaboratively with a major iron ore operator in South Africa. The evaluation focused on reviewing and enhancing the drill and blast management systems, processes, and procedures currently implemented against global good practice.

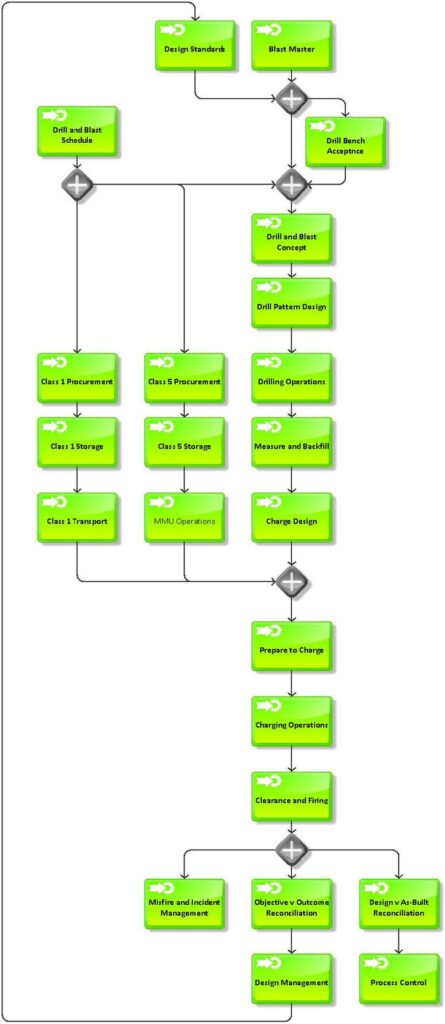

BMI Recommended Blast Processes

BMI firmly believes that all operations can benefit from implementing global good practices, leading to measurable improvements in blast performance and environmental impact, and so resulting in enhanced operational efficiencies, productivities, and economies.

In order to provide a standard for global good practice, BMI has developed a comprehensive drill and blast management system (BMIMS®) that forms the basis of our system audit structure.

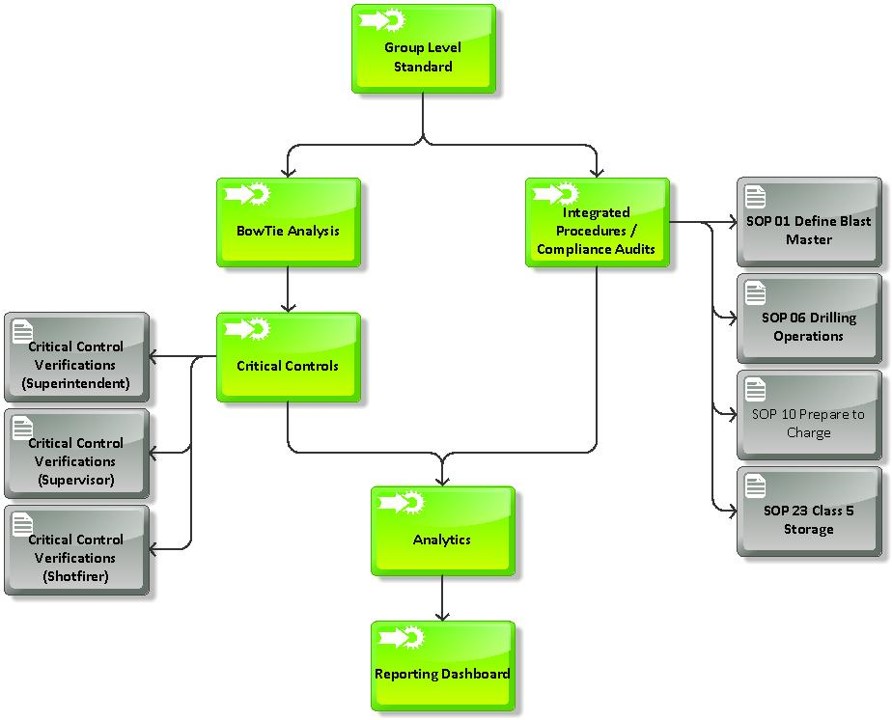

BMIMS consists of an overarching standard underpinned by risk assessments, process models and developed procedures. Details of the applied standard are as follows:

GROUP LEVEL STANDARD

The Group Level Standard (GLS) is the overarching management document that establishes the minimum, mandatory requirements for the storage, transport, handling, and use of explosives at the Group’s Operations. Adhering to this Standard will reduce explosive-related Material Unwanted Events (MUE), minimize High Potential Hazards (HPH), and restrict adverse blasting effects. The GLS should include the following components:

- Roles and Responsibilities

- Incident Categorisation and Reporting

- Material Unwanted Events (and Controls) that can lead to Catastrophic Outcomes

- Standards and Processes – SOPs (Upon which Audits such as these are based)

- Critical Controls and Verifications

- Training Requirements

- Compliance (Standards, Audit Schedules)

- Specific Minimum Standards (Misfire Management, Explosives Storage, Explosives Handling and Storage, Explosives Security)

In support of Group Level Standards (GLS), and to explicitly define the key drill and blast processes, BMI has developed 23 underpinning Explosives Handling and Drill and Blast Standard Operating Procedures (SOPs). We believe, if developed to suit individual operations, and executed, these will address identified shortfalls in systems, processes and technical applications.

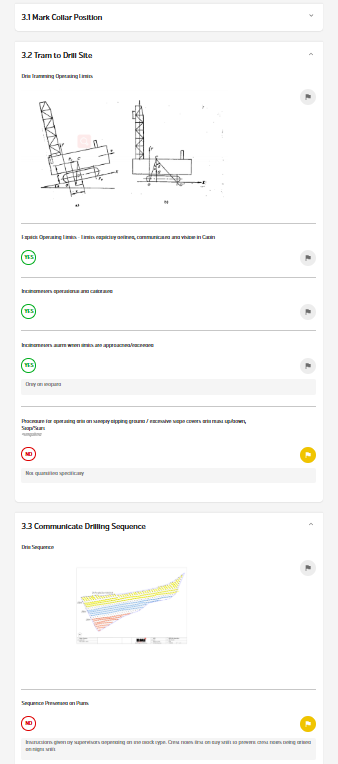

The SOPs have been developed over the past six years and represent industry good practice and are delivered in a way that makes them auditable. Each SOP Audit tool is hosted on a digital platform and specifically aligns to the SOPs.

Site Audit

The audit was conducted in two stages:

Desktop System Audit

The initial phase involved reviewing existing documentation, technical applications, and operational protocols. This step established a baseline understanding of the current systems and assessed their alignment with industry accepted good practices, regulatory requirements, and corporate standards.

On-Site Compliance Audit

The second phase validated the desktop findings by observing practical implementation. This included direct observation of operational practices, personnel interactions, and evidence collection using the BMIMS® digital audit platform. The goal was to assess compliance and functionality under real-world conditions.

Objectives of the Audit

The overarching objective of the audit was to identify opportunities for improvement in the current management systems and provide actionable recommendations. These focused on:

- Optimising performance

- Enhancing safety protocols

- Minimising environmental impact

- Improving overall operational efficiency

Supported by detailed evidence and additional data, the site audit findings offer an overview / evaluation of compliance via the Audit templates themselves and overviews of the process via management dashboards, allowing visual analysis of findings to assist in addressing shortfalls.

This approach ensures a clear understanding of operational practices, adherence to standards, and areas for improvement.

Blast Management International has been engaged by a significant producer of fossil fuels in the Middle East to assist in improving and sustaining their Drill and Blast performance.

This project was initiated in late 2023 with an on-site system audit comprising of both assessing current processes and procedures alongside drill and blast outcomes.

As a result of the findings, BMI has initiated the first stage of its proprietary ‘Integrated Drill and Blast Management System’ (BMIMS). This system tailors procedures, processes, and compliance tools for mining groups or individual sites, which are based on a digital platform. This allows activities to be audited in real time (on bench) with results (positive/negative) to be flagged and uploaded to dashboards such that the operations management can oversee corrective actions.

BMI is convinced that its proprietary BMIMS will result in measurable improvements in blast performance and environmental impact, leading to enhanced operational safety, efficiencies, productivities, and economies.

For more Information on BMIMS and how it can assist your operation please contact us directly!

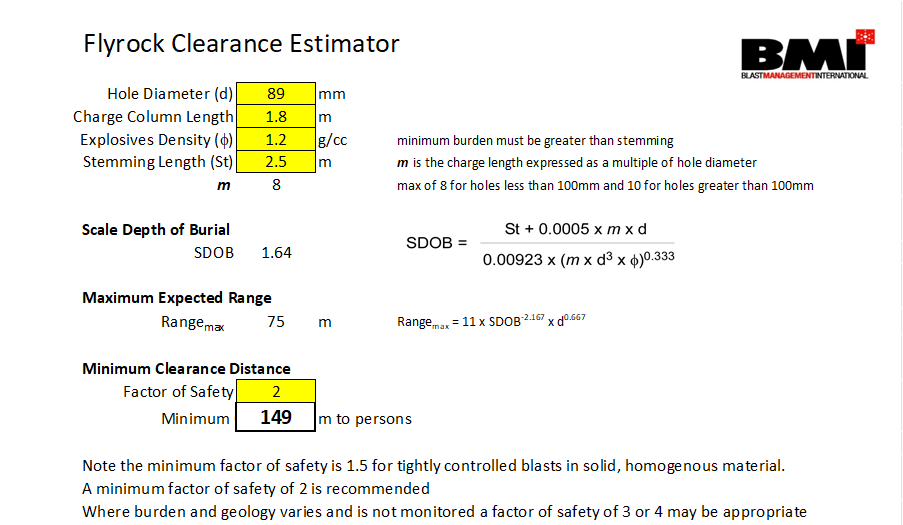

BMI has recently been invited to provide an independent and expert review of documents and evidence provided with regards a trench blast in close proximity to private residences.

The blast produced significant flyrock, resulting in property damage and personal injury, and was under investigation for possible negligence in the application of regulated and best practice standards to the drill and blast function.

From the information given, and application of well understood theoretical principles and abovementioned regulations and practices, BMI provides an assessment on the Blast and the Root Causes of the incident.

BMI will be embarking on a program of on-site auditing and training at a large base metals operation in Eastern Europe.

Starting in July 2024, this will entail site visits to establish how the operation can bring its Drilling and Blasting operations up to Global Best Practices in order to increase throughput, productivity and efficiency,

In doing so, BMI will assess the overall state of D&B, and recommend an optimal model for its D&B operations. BMI will be recommending a program to implement its Integrated Drill and Blast Management System (BMIMS) to ensure findings are implemented in a manner such that operational efficiencies and continuous improvement will carry forward for LOM.

Blast Management International is expanding its presence to Africa, offering comprehensive drill and blast training and consulting services to the surface and underground mining, quarry, and construction sectors.

Our consulting services are centered on the creation and execution of drill and blast management systems, encompassing explosives storage, transportation, and utilization. We specialize in developing site-specific procedures, auditing processes, and compliance tools to guarantee Safe, Efficient, and Sustainable Drill and Blast Outcomes.

With a proven track record in delivering accredited training for drill and blast operations, we are dedicated to representing best practices and developing highly proficient workforces within the industry.

BMI is introducing its highly regarded Drill and Blast Masterclass (to Australian standards of Competency) in Africa in October 2024.

Contact us for more information!

Blasting in Agricultural applications requires very specific additional information and skills to those of conventional drill and blast in mining operations.

Agricultural blasting covers a wide variety of techniques including trenching, ditching, stump blasting, boulder blasting, and the creation of dams, sumps and wells.

Given our knowledge, BMI Africa has contributed to the development of the BMI Course “Agricultural Blasting Operations” for the Australian market. While directed at Australia whose regulations require specific competencies for Agricultural Blasting, the content is no less relevant for use in similar applications in Africa. This training and reference material should be considered as ‘Go-To’ resources for those with activities in this field.