Design and Design Review

Examples of Design in Action...

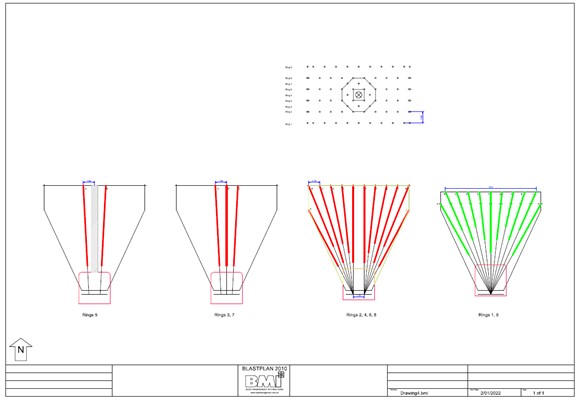

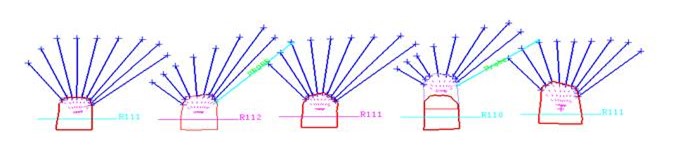

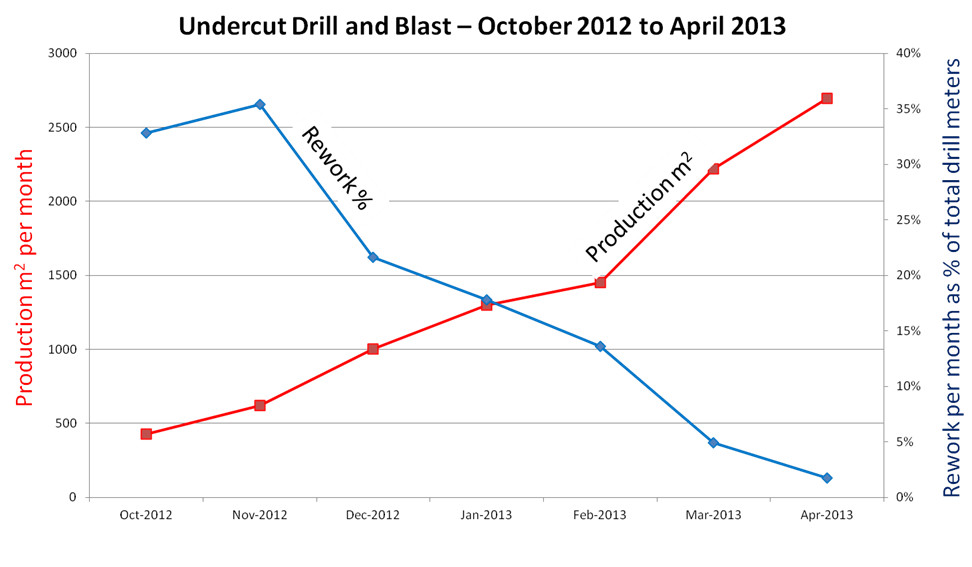

Olympic Dam Slot Re-Design

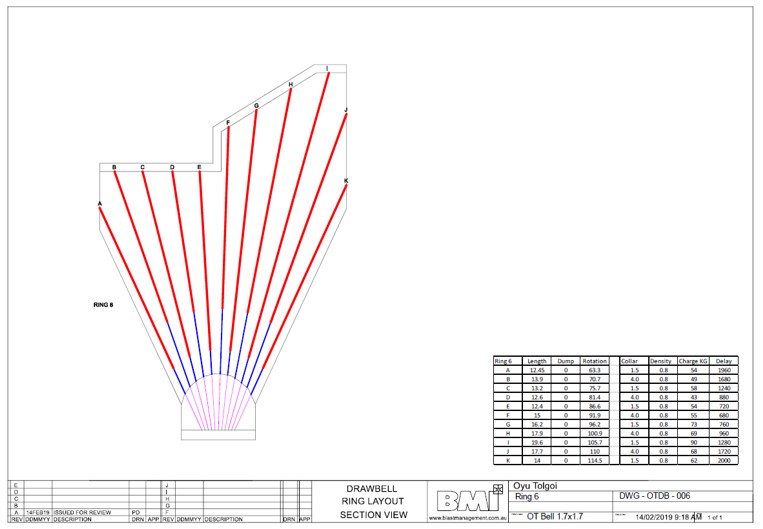

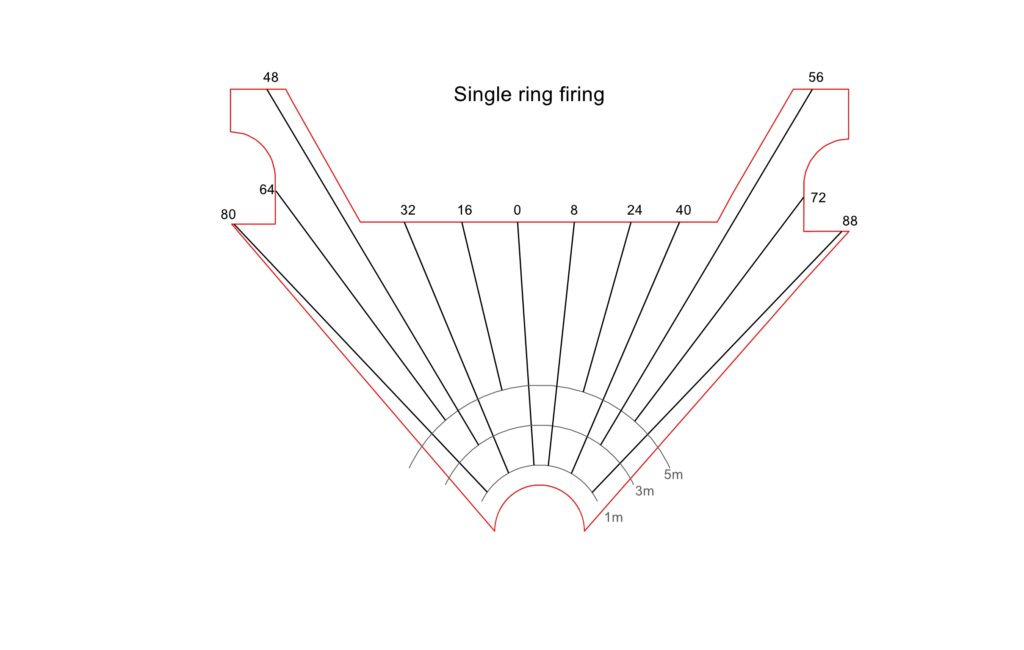

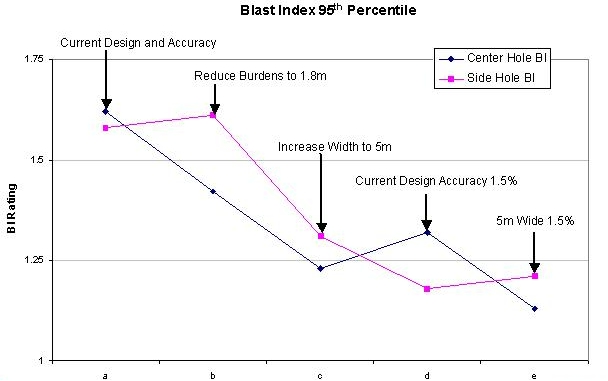

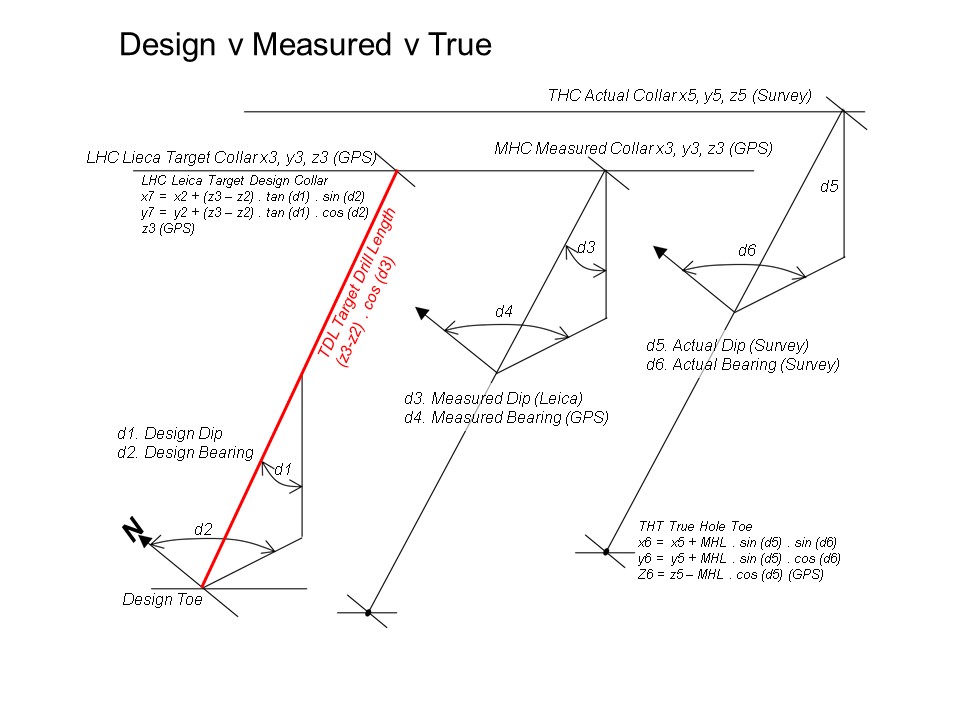

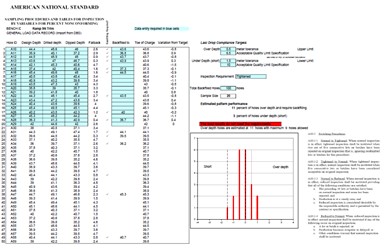

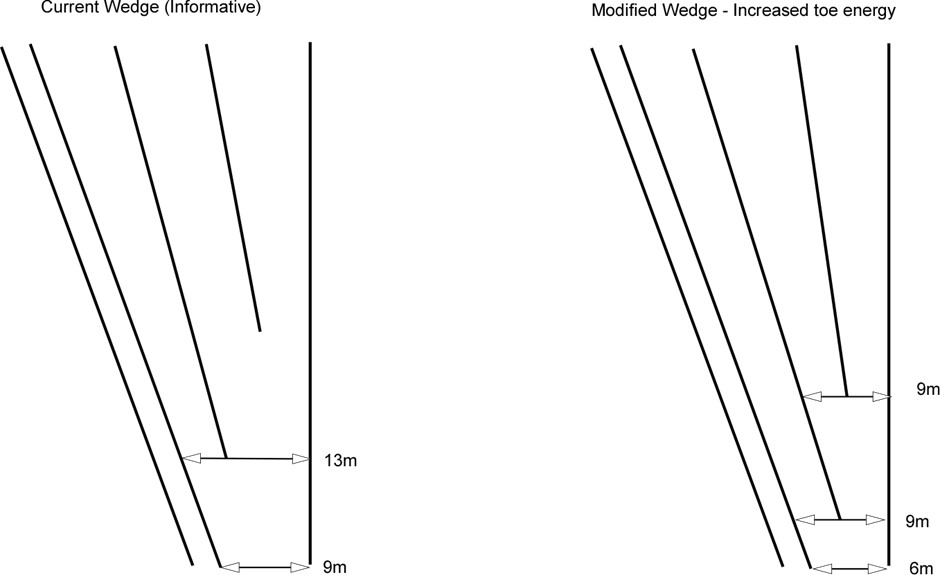

Re-design of the OD slots to reduce sensitivity to drill deviation. This required the development of statistical models to assess the effect of drill deviation when firing raises and slots. The outcome was a widened slot design that delivered an 80% reduction in slot bridges.

The effect of drill deviation in raises and slots was modelled using monte-carlo analysis. This enabled a range of designs to be assessed for sensitivity to drill error.

Interactive Timing

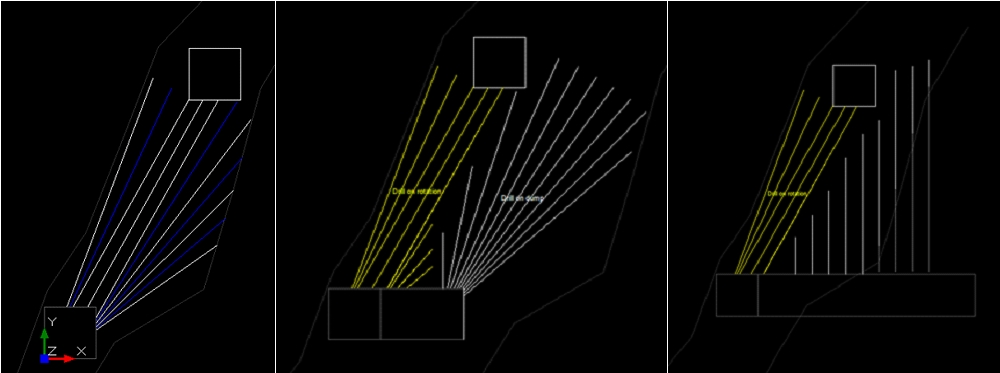

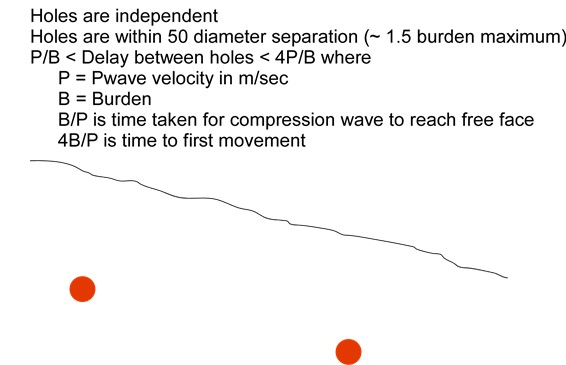

Interactive timing is a concept where independent holes are fired with reduced time separation so that the material around the holes is impacted by energy from multiple holes.

Interactive timing is not realistic for dependent holes owing to the requirement for burden relief.

Interactive timing is relevant for holes within a maximum distance of around 1.5 burdens:

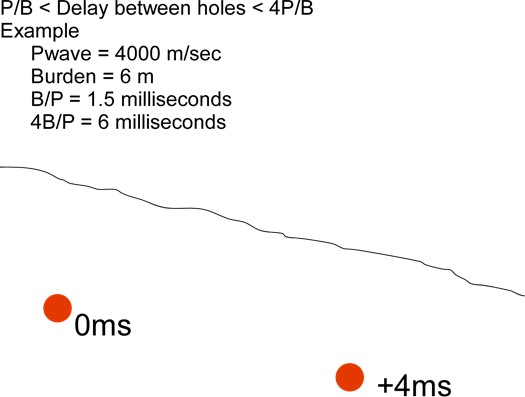

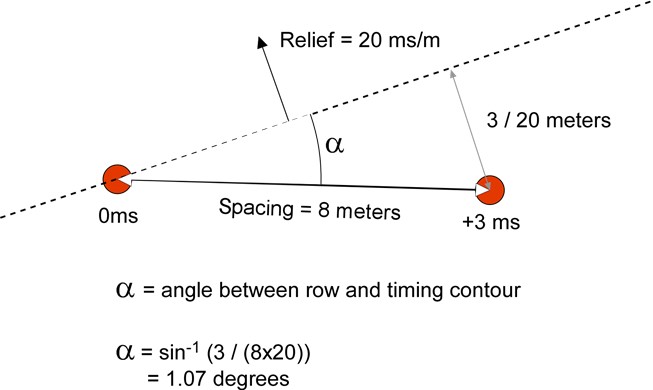

The delay between holes is not before the compression wave reaches the free face and before first movement. In the following example interactive timing is between 1.5 and 6 milliseconds.

Note the distance between holes (spacing) the burden and the P wave velocity all influence interactive timing. Therefore there is a not a single ‘right’ delay between or within a pattern but rather a range of delays to meet the requirements of interactive timing.

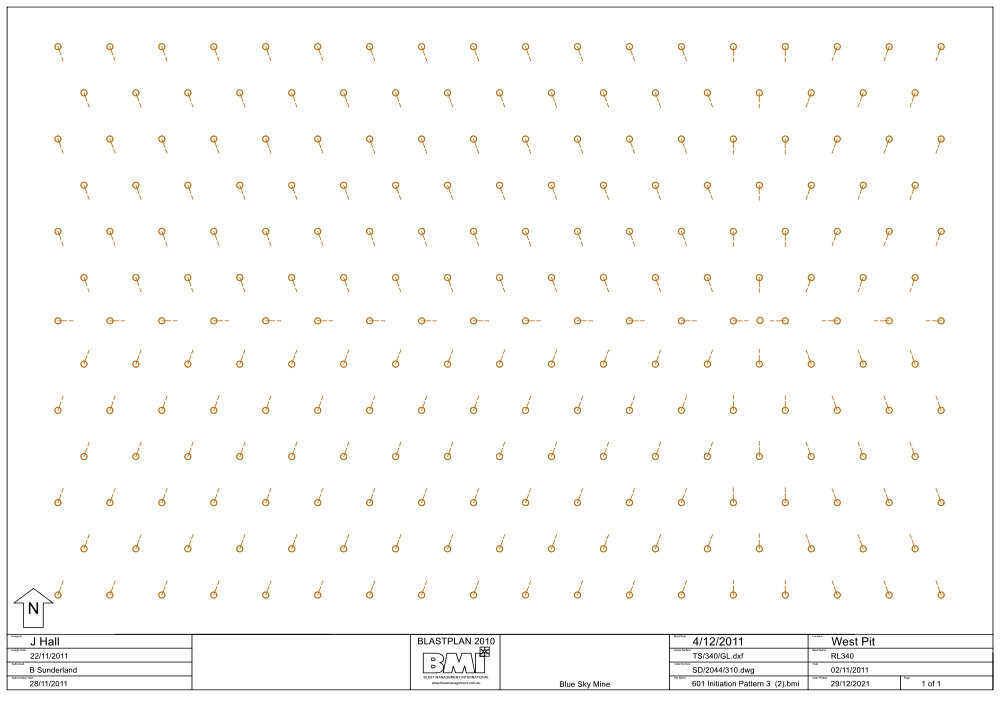

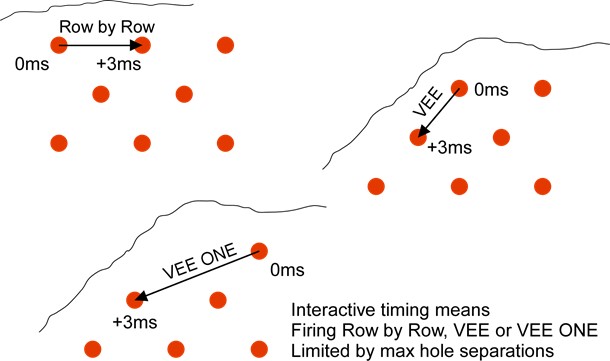

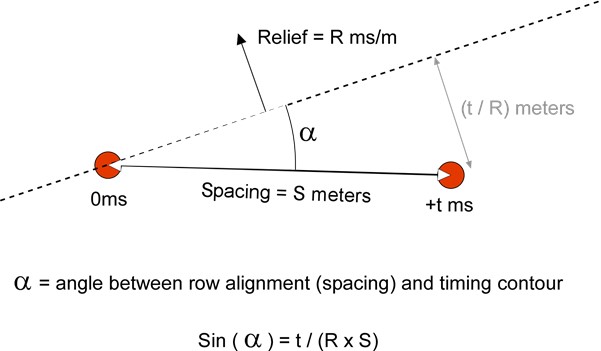

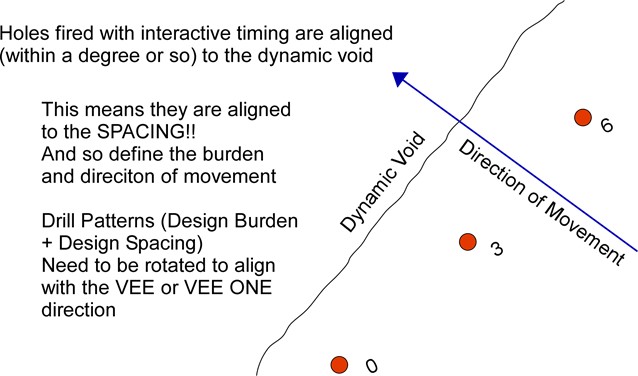

The application of interactive timing determines the true burden and spacing. These should be considered in drill pattern design.

Rather than blindly aligning the rows to the available free face or blast perimeter consideration should be given to aligning the rows (spacing) perpendicular to the expected direction of movement.